Add to Cart

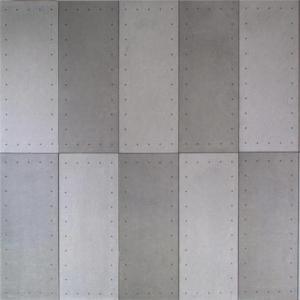

Non-Flammability 100% Non-asbestos Cellulose Waterproof Fiber Cement Board Wall Panel UV Coated Decorative

Product Introduction:

fiber cement board is a kind of high-density multi-functional building materials. Its main components are cement, natural organic fiber, artificial fiber and other assistant materials. It owns excellent machining performance. It is a stable performance and light weight building &decoration board used cement as major

and natural fiber reinforced,with the process of pulping,emulsion,forming,pressing,autoclaving,drying and surface treatment.With the sanding surface,thickness uniformity is better and grain is clearer.And because of the cement,the strength is higher,and waterproof performance is much better.

Specification:

(1). Thickness: 4-25mm

(2). Standard size: 1220*2440mm or 1200*2400mm

(3). Note: other specification is available

|

Product |

Normal Fiber Cement Board |

|

Dry Density(g/cm3) |

1.2-1.3 |

|

Water absorption (%) |

33-40 |

|

Wet expansion (%) |

0.25 |

|

Water Content(%) |

13-20 |

|

Bending Strength(Mpa) |

9-16 |

|

Shrinkage rate(%) |

0.15-0.2 |

|

Frost resistant |

No delamination and crack after 25cycles under freezing and thawing |

|

Water penetration |

No water drop on the board surface after 24hours |

Product Application:

Exterior wall cladding; interior (toilet) partition;sound absorption ceiling; curtain wall scale board;composite wall panel;outdoor billboard; thermal baffle;floor tiles.

Fiber cement board is extensively used in office building,hotel,hospital,facatory building,school,villa theatre and other kinds of art building.

Main Features:

1. 100% Asbestos Free

2. Excellent Fire Resistant

3. Excellent Moisture / Water Resistant

4. Good Heat and Sound Insulation

5. High Strength

6. Stable Dimensions

7. Durability and long service life

Packing:

1. Strong wooden pallet(Standard Export Package)

2. Corner protective

3. Plastic Film

4. Protect Board

Partition Installing Method:

1. Galvanized Metal Frame

a.The top and bottom keels are fixed respectively top floor and on floor with expansion bolts.

b.The vertical keel should be aligned well according to the requirement (generally being 612 mm) with

laterally supporting keel installed.

2. Board Material Package Fixed

a. Cutting the board material to the dimensions needed (about 10mm lower than wall height)

b. Board material is fixed on keel in anchoring seam way with tapping screw: the interval of tapping screw is generally

about 200~250mm with screws sinking 0.5mm under the board face.

c. The expansion seam of about 4mm between boards should be kept.

d. The shrouding should be fixed from the middle to the four sides and cannot be operated at multipoint simultaneously

to avoid generating inner stress to make board material bucking.

e. Before board being packaged and fixed, depending the needs, glass cotton or rock cotton can be filled.